You have no items in your shopping cart

Using a Homogenizer for Blending Terpenes into Vape Cartridges

- Posted on

- Posted in Homogenizer, How To Guides, Terpenes

- 0

Read this blog in its entirety to better understand how to mix vape cartridges to achieve uniform test results of THC, CBD, and Terpene percentages throughout all of your vape cartridges. For anyone making 10 to 10,000 vape cartridges, there is a scalable solution for you.

Call us at (510)-487-1390 or Email at [email protected] with any questions about mixing distillate or help setting up a homogenizer.

What is in a Vape Cartridge?

A vape cartridge usually consists of only two types of ingredients. The active main ingredient are the cannabinoids like THC, CBD, etc. which are typically distilled and do not have any smell or flavor so flavonoids and various other terpenes which occurs naturally in the cannabis plant are added to give the vape some character.

Distillate is an exciting and versatile product. Distillation of cannabis plant extracts can produce a consistent oil of nearly pure cannabinoids that's great for a variety of uses within the cannabis industry. It's often used in the production of vape cartridges, edibles, and MCT oil (medium chain triglycerides) tinctures or lotions; however its high viscosity makes these tasks challenging at best without careful preparation methods!

Terpenes are a class of highly volatile compounds that are produced by a wide variety of plants, including cannabis plants. These molecules commonly referred to as essential oils by many wellness professionals are responsible for the characteristic aromas of many fruits and flowers, have a range a health benefits, and they also play an important role in plant-to-plant interactions.

In cannabis, terpenes are produced in the glandular trichomes that cover the surface of the leaves and flowers. These molecules can be extracted from the plant material using a variety of methods, including steam distillation, solvent extraction, and supercritical CO2 extraction. Once extracted, the terpenes can be used to improve the taste and smell of cannabis products, or they can be added to vape pens and other cannabis products to enhance their effects.

What is a Homogenizer and Why is it Needed for Adding Terpenes into Vape Pens?

A homogenizer is a high shear mixer that homogenizes, or emulsifies substances. Emulsification is the process of creating an emulsion, or mixture, of two or more substances that ordinarily would not mix together.

In the case of homogenizing terpenes and distillate for vape pens, the homogenizer helps to create a uniform mixture of the two substances so that they can be used together in cartridge fillers and cart-fillers. This uniformity is important because it ensures that the filling machine is consistently filling each cartridge accurately, will not clog, and fills each cart quickly. Without a homogenizer, it would be impossible to achieve the level of consistency required for an automated cart filling machine, and the vape cartridge would not work as well, leading to poor customer experience or recalls.

Choose Your Homogenizer

The correct homogenizer is determined by the batch size you are going to run. There are small, medium, and large sized homogenizer kits to fit different needs. A smaller homogenizer is best for samples and is portable to be brought between facilities. Where a medium and large unit are securely mounted and are used for commercial runs. Each homogenizer can mix its corresponding batch size within a minute.

X-120 Homogenizer Kit for Viscous Oils

Smallest of the homogenizer kits meant for sample sizes during r&d. Use this model for testing new flavors, as larger homogenizers require a minimum amount that may be too large for a sample size. Easy to bring between different facilities for different strain and batch testing. Be sure to use a proper tall form beaker to properly submerge the shaft in its entirety.

X-1000 Homogenizer kit for Viscous Oils

Our mid-range mounted homogenizer is great for commercial production. Capable of homogenizing bulk amounts of oil throughout a day. At least enough oil must be used to submerge the homogenizer blade, making it less suitable for sample batches as the minimum oil requirement is significantly higher based on the vessel used.

X-1740 Homogenizer for Viscous Oils

This homogenizer is great for large scale, mass production. Capable of producing enough oil for thousands of cartridges a day. Able to keep up production with most automatic cart fillers to prevent any bottlenecks in manufacturing. Comes with two sizes of shafts, a G30 and G40 based on production size.

Heating your distillate is important

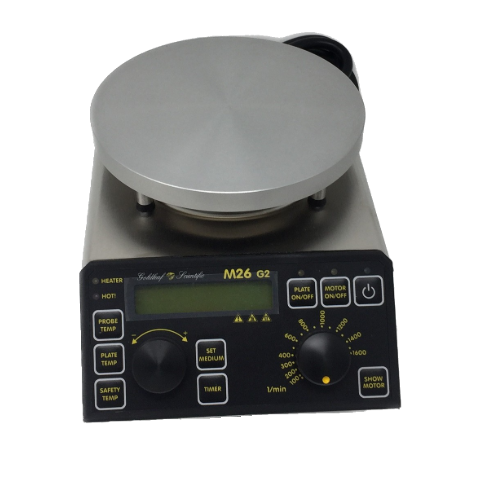

Hotplate stirrers are excellent for temperature control during processing, and homogenization. They provide the even and controlled heating required for homogenizing viscous mixtures such as blending cannabinoids and terpenes. The temperature is set between 70-90°C, which is the recommended level by most producers in the cannabis industry. Using digital magnetic hotplate stirrers ensures that the cannabis extracts are not heated too far beyond this point to prevent damage from occurring.

Prevent Overheating

Since the value of material being processed is quite high, it is important to select a hotplate with safety mechanisms to prevent damaging material. More advanced hotplate stirrers such as our M26G2 have built in safety features that correct itself or shut down if something goes wrong. For example, if the external temperature probe becomes dry or the liquid level becomes too low it will shut off. Consequently, the digital magnetic hotplate stirrer is a necessity for manufacturers to create quality products.

How to use a homogenizer for mixing terpenes and distillate

Gather your materials

To use a homogenizer for mixing terpenes and distillate, you first need to gather your materials. This will typically include a homogenizer, a hotplate, a healthy supply of decarboxylated cannabinoid extract such as distillate, and a fresh supply of terpenes. You will also want to have a clean cartridge filling machine and workspace to prevent contamination.

Begin Heating

Once you have your materials assembled, start by adding your distillate to a vessel and place on a hotplate and begin heating. It is important to do this in small batches as you want to mix and process the mixture thoroughly. We recommend to never exceed the maximum capacity of the homogenizer system based on the viscosity of the material.

You can use open to air vessels such as heavy wall beakers for temperature stable materials and a sealed vessel for oxidation prone materials or materials which foam excessively (“G” series sealed shafts can be used under vacuum/pressure).

Start Homogenizing

After the distillate is 70-90°C pour in a measured amount of terpenes and begin blending these ingredients together starting at the low speed setting on the homogenizer, and in a quick and controlled manner increase the speed to nearly full power. Continue mixing for 20-45 seconds or until you achieve an even and homogenous consistency throughout your mixture. A light supply held at an angle to reflect off the surface can provide a visual que as any streaking or off-color differences are a sign of an incomplete mixture. After your homogenization is complete, you are ready to fill your cartridges and get started vaping!

How much terpenes do you add into vape carts for best results

When working with vape pens and other similar devices, one of the most important aspects to consider is the amount of terpenes that you add. Generally speaking, terpenes enhance the flavor and effect. However, there are also several considerations to keep in mind when mixing terpenes for vaping.

For example, cannabis derived terpenes produce the highest quality products but are generally very expensive so the producer must carefully consider this cost into the final product. Using too high concentration of terpenes will squeeze margins, or can cause the product to become harsh when using as the terpenes over a certain threshold is an irritant to the lungs, throat, and eyes.

Find What Works

This level is not the same for everyone as some people are more sensitive to different types and amounts of terpenes. As a general rule of thumb, we suggest anywhere from 5-10% of terpenes to distillate, where 5% is fairly low but still very enjoyable and 10% is so high that some people might be turned off.

As prices have fallen recently, I generally lean on the lighter side, but it is important to experiment and explore what works best for your terpene blends and market. By understanding these key factors and using a homogenizer or other equipment designed for mixing terpenes/additives, you can create customized vapes that deliver the best possible results.

What are the benefits of using a homogenizer for mixing terpenes and essential oils into vape cartridges?

A homogenizer is a machine that is used to homogenize, or mix, two or more substances together. In the context of cartridge filling, a homogenizer can be used to mix terpenes into cannabinoid extracts or vape pens cartridges evenly and efficiently.

Terpenes are compounds found in plants that give them their distinctive smell and flavor, and offer other potential health benefits. When vaping, these compounds can be added to the vape pen cartridge to enhance the flavor of the vapor. Most terpenes or structurally non-polar which one might assume would easily dissolve and mix into a cannabinoid extract, but terpenes are often not completely soluble in a heavy and thick oil liquid.

A homogenizer can help to solve this problem by breaking down the terpenes into smaller droplets and distributing them evenly throughout the oil. This ensures that your filling machine will be consistent and each puff of vapor from the cartridge will taste the same and that the terpenes will not settle at the bottom of the cartridge over time. Consequently, using a homogenizer is an effective way to ensure that vape pen cartridges are filled with a consistent and flavorful mixture.

Tips for using a homogenizer

Keep Clean!

One of the biggest issues for working with a heavy and thick fluid is cleaning. For distillate this is incredibly important because as the material touches the shaft internals the surface will become sticky or crystallize, and will cause excessive stress of the shaft and motor and lead to damage. Even a small amount of time will allow the material to cool and could cause the shaft to become unable to restart with the motor.

Failure to clean and maintain the system regular will cause damage to the internal components of the shaft which are precision manufactured to tolerate operating at up to 33,000 rpm. See our G shaft cleaning guide here

Don't Ignore Signs of Wear or Friction

In order to function optimally the rotor/stator edges should be sharp without any signs of wear such as pits or burs. It should be noted that these items are consumable and are expected to wear with time. However, poor maintenance and overuse before replacement can cause a host of issues. The short time to homogenize (20-45s) can become 2-10x longer to achieve the same results. This can cause the terpenes to alter their scent characteristics and generally leads to a darker end product.

The damage usually gets worse over time which causes excessive wear on parts and friction. Some shafts once damaged will friction heat to such an extent it will burn or damage your batch which can be extremely costly. Should you notice any friction or rubbing while hand turning the shaft then do not use and contact Goldleaf Scientific for shaft repair or refurbishment.

Use a Drive Stand Assembly

Always use a sturdy stand to support the homogenizer. Hand fatigue could in extreme cases cause the generator to strike the container and break it. Another point: It’s difficult if not impossible to control the speed of the generator drive motor when holding the unit.

The takeaway: Always use the drive stand assembly recommended with Goldleaf homogenizers. Although we do offer what we bill as the X120 hand held drive, we also recommend using the drive stand assembly with it.

Don't Put the Disperser Directly in the Center

Another tip often overlooked from the owner’s manual is that you need to keep the homogenizer shaft off-center while in use. For maximum effectiveness, the generator should be stably positioned to remain offset from the bottom of the flask or beaker holding samples. This avoids a vortex. There’s also the danger of causing contents to splash from the container if the operator is not paying close attention.

How does a Goldleaf Scientific Homogenizer compare to others?

It's Robust and Designed to Last

Designed for the toughest challenges in research and industry, these industrial grade mixers can handle any task that comes their way.

It's Modular

The high shear homogenizers are modular and easily configurable for a variety of tasks and applications. From cell fractionation using the knife style generator to aqueous blending using the fine generator, but the feature that really sets our homogenizer apart is the sealed homogenizer shaft system.

It is More efficient

With its slanted slots, the Goldleaf homogenizer provides a 25% efficiency increase on standard ones. This means that it can mix media more efficiently and prevent overheating due to prolonged use without sacrificing quality control or speed of process time.

It is easy and quick to change dispersers for different applications

Goldleaf Scientific's interchangeable Rotor-Stator assemblies allow for quick switching between tasks by providing special tools that can be used with generators. The high circumferential speeds attained from our combination sonic energy and mechanical shearing creates ultrasonic cavitation in the media, assisting very efficiently at making sure your samples are well homogenized!

It has a Sealed Shaft Disperser

Most companies homogenizer system requires that material flow through the shaft, but this will not work well for sticky viscous or abrasive materials. Another issue is that some material will foam while being homogenized so the processor will typically require a shaft capable of withstanding high pressure. Our patented "G" series sealed shafts are makes Goldleaf Scientific homogenizers the preferred for users in the cannabis industry- they feature superb German engineering with expert craftsmanship!

Goldleaf offers world class support and offers rapid repairs

We take special pride in our products and we have intimate knowledge of the products we design, manufacture, and sell. Unlike other companies we fully support our products. Our aim is to fix your problem in 48 hours or less and we have the tools on hand and the parts in stock to make sure you are back up and running asap.

What about bubbles?

Although it seems that bubbles would be the worst thing for homogenizing terpenes with cannabinoid distillate the timing which we choose to remove them makes our lives much easier. We could get a sealed chamber and remove the bubbles prior to homogenization, but that would be difficult to achieve. Once the homogenizer is powered on it is going to create new bubbles with the atmosphere in the container, so why not use this to our advantage because there is good evidence that bubbles in help increase the homogenization of the materials. Although the function is not clear, the thought is that the bubbles cling to the rotor/stator and help create a greater surface area.

Removing Bubbles

To remove the bubbles you can add to a sealed vessel such as a round bottom flask and pull vacuum, then bleed in with inert gas and repeat 2-4x. This can also be done after the cart filling operation by placing the filled carts into a glove box or vacuum oven and then completing the above mentioned purge/back-fill

Need Help Finding the Right Equipment?

Call us today at (510)487-1390 for assistance in selecting the right homogenizer setup based on your processing capacity. The more you plan to mix, the larger homogenizer you will need. We have complete kits available here, just select the proper shaft. For mixing any distillate, you will be using a G-type shaft will Viscous (V) blades.

Again, feel free to call at (510)487-1390 or email us at [email protected] for more information. Our kits are designed to work especially well with thick, viscous oils such as distillate and are perfect for making consistent products. These homogenizers ensure all products will have consistent test results so the first cartridge and the 1,000th cartridge will have the same THC/CBD/Terpene percentage throughout the entire batch.

We have more in depth blogs about homogenizers here:

Homogenizers for Viscous Materials

Homogenizer Shaft Selection Guide

Homogenizer Shaft Cleaning Guide

Guide to Rotor Stator Homogenizers

Comments

Be the first to comment...